MR092M Automated Pallet Storage Equipment Vocational Training Equipment Automatic Training Equipment

I. Product overview

1.1 Overview

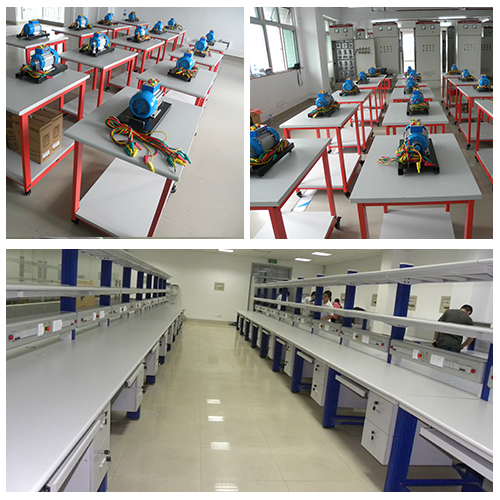

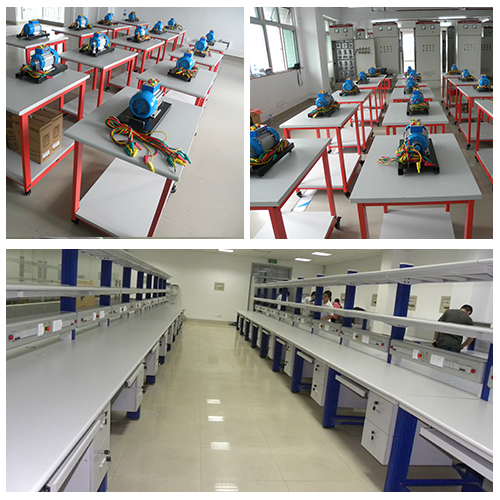

This training device is mainly composed of various types of industrial sensors, pneumatic control units, electrical switches, PLC programmable logic controllers, human-machine interfaces, etc. It consists of silo units, conveyor belt modules, RFID sensors, vacuum suction cup handling modules, A mechatronics equipment mechanical platform composed of two-axis manipulator handling modules, three-dimensional storage modules, touch screen units and other workstations. Through related experiments, you can be familiar with the operating characteristics of pneumatic system actuators. Based on the Siemens 1200 PLC motion control system, touch screen and PLC communication methods, etc., students can cultivate the corresponding knowledge and skills, suitable for higher vocational, college, secondary vocational schools and related majors in technical schools Teaching and skill training assessment

1.2 Features

(1) The training platform adopts aluminum alloy base plate to build the training platform with a stable structure. Each actuator module is placed on the base plate, which is easy to use and not easy to damage.

(2) The power distribution and PLC control unit of the training device adopts the switchboard mode, the power supply of the system is drawn through the safety plug, and the wiring of the training device is connected through the wiring, which is safe and reliable.

(3) The organic integration of mechanical technology (including pneumatic technology), sensor technology, PLC control and communication network technology reflects the characteristics of the production process of modern manufacturing. The overall structure adopts open and disassembly type, which can easily replace the modules. The content of the modules is determined according to the principles of productive functions and integrated learning functions, so that the required modules can be easily selected during teaching or competition.

(4) The I/O terminals of the master and slave PLC modules of the training and assessment device are connected to the command switches, photoelectric switches, sensors and indicating components through the terminal block.

II. Performance parameters

(1) Input power: three-phase five-wire system AC240V±10% 50Hz

(2) Dimensions: 1250mm×750mm×800mm

(3) Machine capacity: <1.5KVA

(4) Weight: <80kg

(5) Working conditions: ambient temperature -10℃~+40℃ relative humidity <85% (25℃)

III. Product composition

3.1 Power input unit

The power input terminal is placed in the power distribution area on the training platform, led out through the plug, and the total power supply of the system is controlled by the leakage circuit breaker.

3.2 Training table

The training platform is composed of an aluminum alloy substrate, which can be placed on a horizontal table for experiments, with a firm structure and beautiful appearance.

IV. Can complete the training content

(1) Debugging experiment of solenoid valve controlled pneumatic actuator

(2) Installation experiment of Siemens 1200 programming software

(3) Configuration and programming experiment of Siemens 1200 programming software

(4) Simens 1200PLC simple programming experiment

(5) Siemens 1200PLC and human-machine interface Weiluntong touch screen communication experiment

(6) Siemens 1200 PLC control operation experiment

(7) Siemens 1200PLC servo positioning experiment