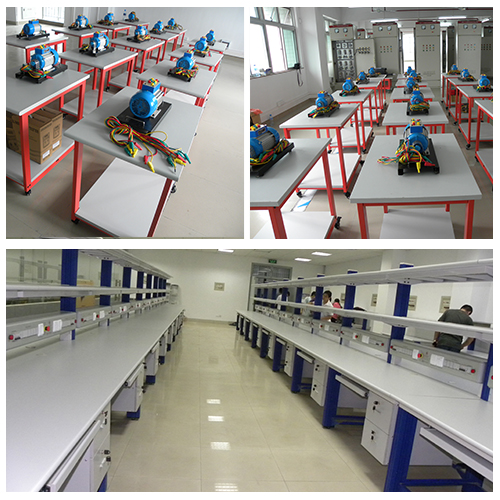

MR278E Electrical Machine Trainer Educational Equipment Electrical Engineering Lab Equipment

This trainer include various types of DC motors, AC motors, through experiments students can be familiar with DC motor features, AC motor features, master its control principles and control mode, it will cultivate students’ technical skills and knowledge. The trainer is suitable for vocational school students, technical schools students, colleges students who major in electrical technology, electronics technology,mechatronics technology etc.

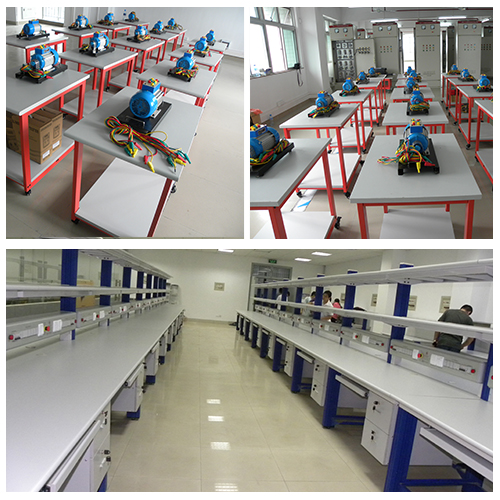

The machine system shall be designed for electrical teaching laboratories. The unit shall consist of a steel or wooden cabinet with working surface and storage facilities for all modules associated with the system. A mounting rack fixed on the top surface of the supply console shall be provided for vertical mounting of the component modules in use. Power for the operation of the module shall be obtained from a plug-in modular typed supply console also mounted on the surface of the cabinet.

Supply Console

The supply console shall provide the following features:-

1.Output voltage of 0 – 415V AC 3 phase 10A variable supply.

2.AC variable output of 0 – 240V / 5A single phase.

3.DC variable output of 0 – 240V / 5A stabilized and regulated.

4.Instrument to monitor output voltage and current.

5.Pilot light to indicate live supply.

6.Push button control for all output.

7.Emergency stop mushroom-head push button is incorporated in the unit.

8.Input 415V AC 50Hz.

All supplies shall be isolated and provided with overload and short circuit protections (30mA). The ampere output shall also be suitable for all component machines and other accessories connected. Output terminations shall be at 4mm terminal posts or other suitable sockets capable of accommodating 4 mm stacking jacks.

Electrical Machine Modules

Machine modules for the system are to consist of motors with quick release, mounting, coupling facilities, double shaft ends and be thermally protected. Machine termination shall be at 4 mm terminalposts mounted on an insulated panel with engraved standard international symbols and markings. These termination panels shall be rigidly fixed to the body of each machine. The following are the modules and ratings of components machines.

1.DC series motor / generator suitable for operation as DC series motor, Universal motor and self excited or separately excited generator. Approximately 300W / 220V. Double shaft end.

2.DC shunt motor / generator suitable for operation as motor and generator, self or separately excited. Approximately 300W / 220V. Double shaft end.

3.DC compound motor / generator. Suitable for operation as motor and generator. Approx. 300W / 220V. Double shaft end.

4.Single phase AC induction split phase motor. Approximately 300W / 220V. Double Shaft end.

5.Single phase AC induction type capacitor motor. Squirrel cage rotor. Suitable for operation as a Capacitor start, capacitor run and capacitor start and capacitor run motor. Approximately 300W / 220V. Double shaft end.

6.Three phase induction squirrel cage motor. Approximately 300W / 220 / 415V star connected. Double shaft end.

7.Three phase synchronous motor/generator. Suitable for operation as motor and generator. Approximately 300W / 415V star connected. Double shaft end.

8.Three phase slip ring induction motor. Approximately 300W 220 / 415V. Double shaft end.Three phase induction motor. Squirrel cage rotor with pole changing. Approximately 1400 / 2800 RPM, 300W / 415V.

9.Double shaft end.

10.Repulsion motor. Single phase with brush shift facility. Approximately 300W / 220V 50Hz. Double shaft end.

11.Brake machine unit suitable for the above machine modules and fitted at one end with a compatible tacho generator.

12.Fault simulator, plug-in type, suitable for 3 phase motor in the trainer systems, with fault programming through switching.